Quality assurance is critical to securing lasting business.

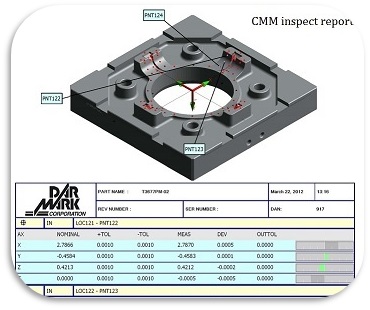

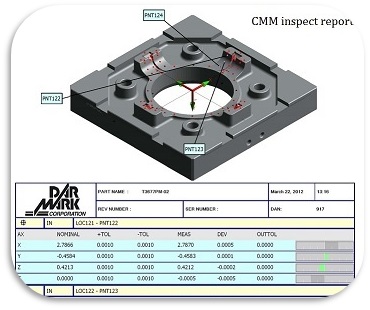

ISO9001:2008(Cert No.07614Q12249R0S) quality system has already apply strictly. During the processing, the quality be controlled by technicians. Check and analysis customers drawing/CAD, finalize mold structure, moldflow analysis report, decide the molds processing technique, design 3D mold model, choose suitable steel material and mold components, following processing schedule on spot workshop daily, Each inserts including electrodes be inspected by CMM,Optical Projector or Sclerometer measure equipments,all these reports below will be provided to customers for reference.

1). Customers part structure analysis report and suggestions.

2). Mold structure report(as: parting line, gate, pins,sliders, lifter...) and suggestions.

3). Mold flow analysis report.

4). Purchasing items inspect sheet.

5). Certificate of all steels.

6). Steel heat treatment report.

7). Mold inserts and electrodes inspect report.

8). Weekly process schedule.

9). Injection molding parameter data.

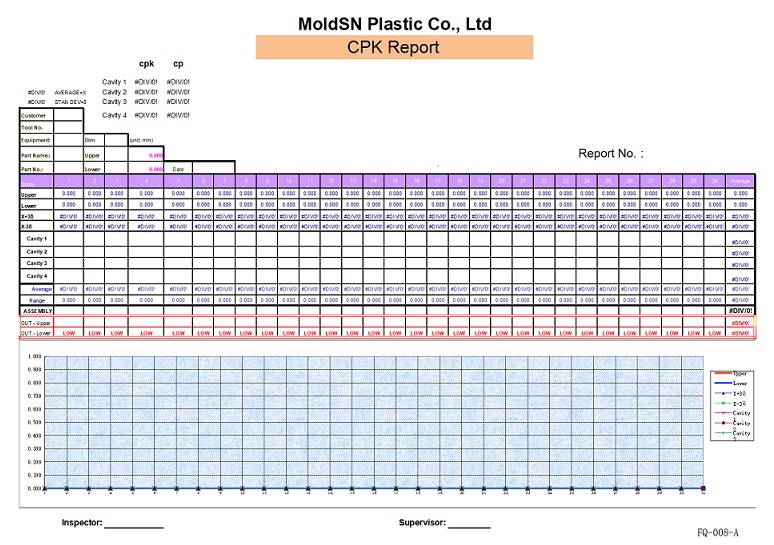

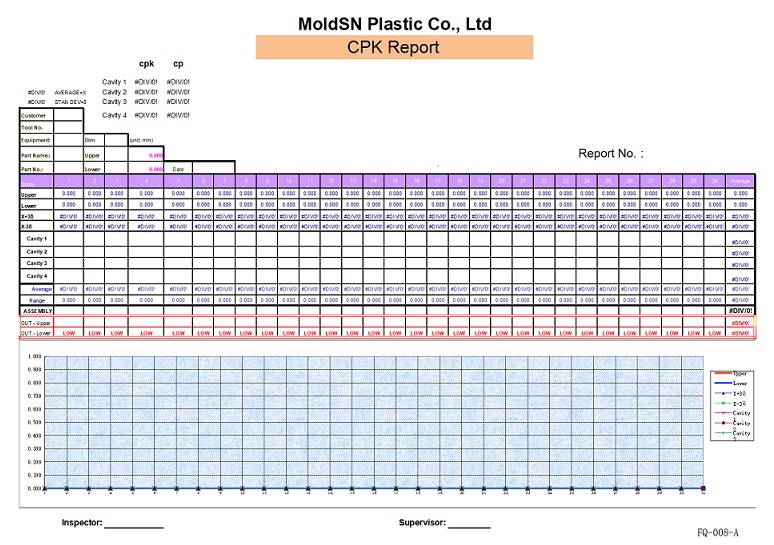

10). First sample inspection report.

11). CPK or PPAP report if required.

12). Certificate of plastic resin.

13). One hour mold run video.

Having various large-scale processing equipments and testing instruments:

1) . Large gantry CNC, stroke range (mm): 3000x2000, 2000x1500, 1600x800;

2) . Precision CNC, stroke range (mm): 1200x800, 850x600, 650x350;

3) . Electric discharge machining mirror surface, electric discharge dual head machining;

4) . Slow precision wire cutting Sodick;

5) . Precision grinding/milling/lathe;

6) . Mold placement machine;

7) . Injection molding machine: 60 tons to 3600 tons;

8) . Elevators: weighing 5, 10, and 20 tons;

9) . Coordinate measuring machine.

10) . Scleral gauge;

11) . Contour projector;

12) . A workshop of 2000 square meters;

13) . We have 20-years mold manufacturing experience.

Quality assurance is critical to securing lasting business.

Quality assurance is critical to securing lasting business.